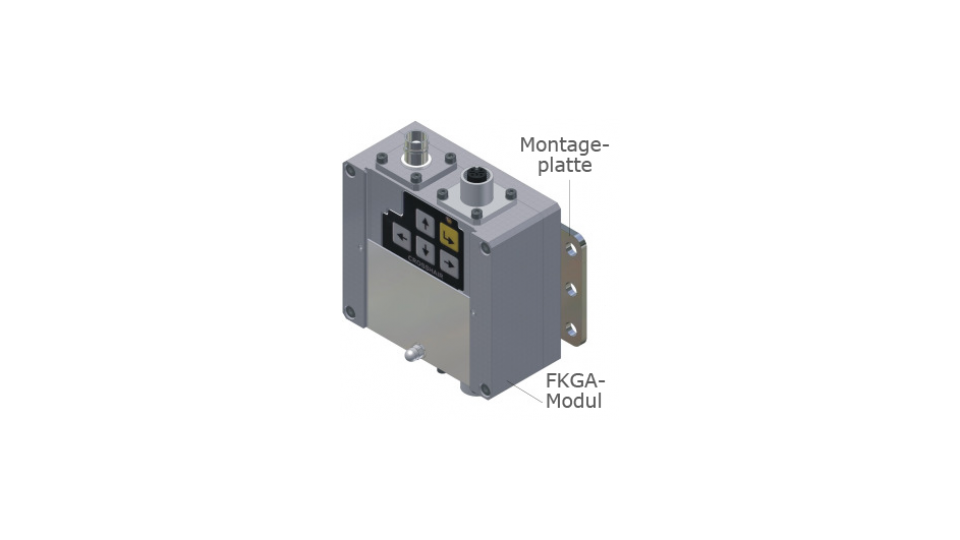

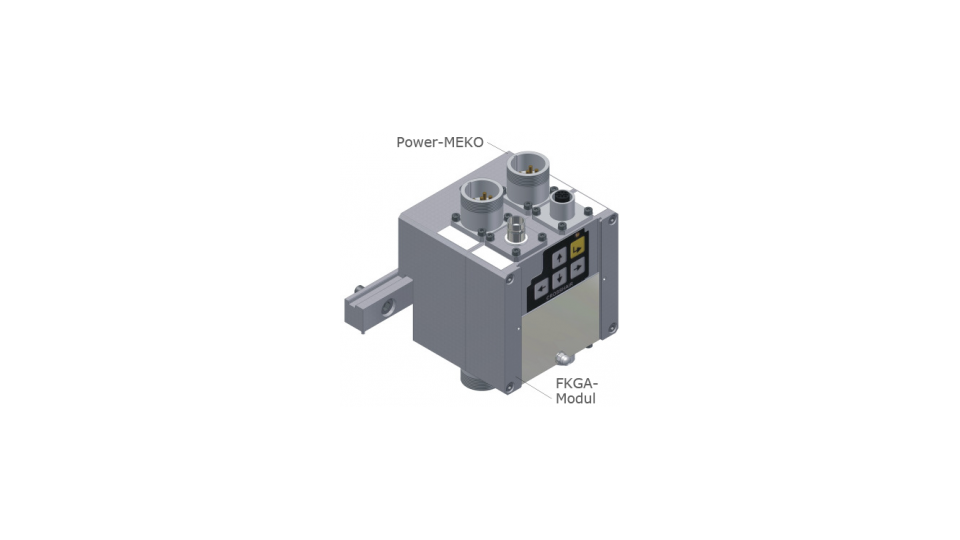

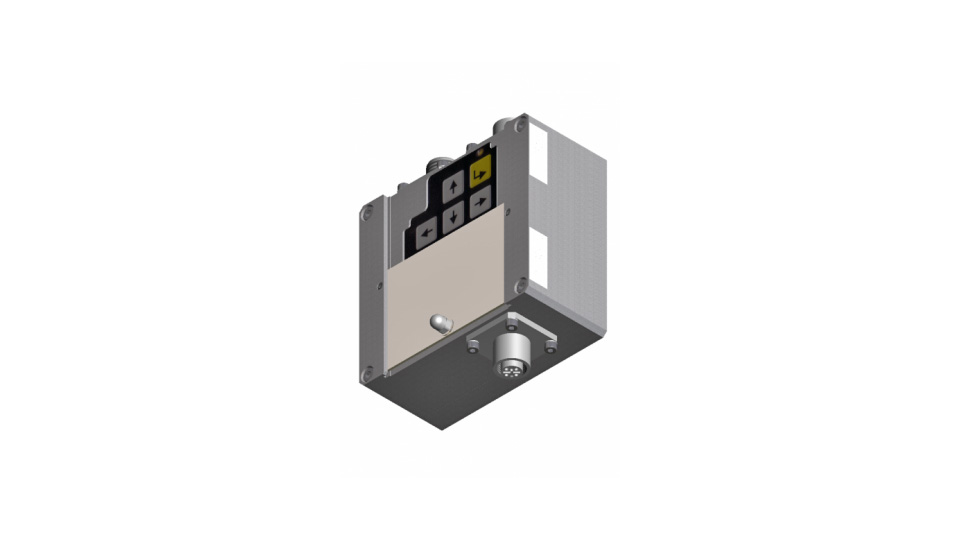

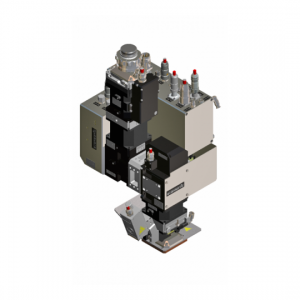

FKGA

FKGA

The crosshair generator makes it easier to set up the laser process with crosshairs superimposed in the camera image. This visualization of the laser spot helps the operator adjust the application to the actual laser spot and avoid inaccuracies between the pilot laser and processing laser.