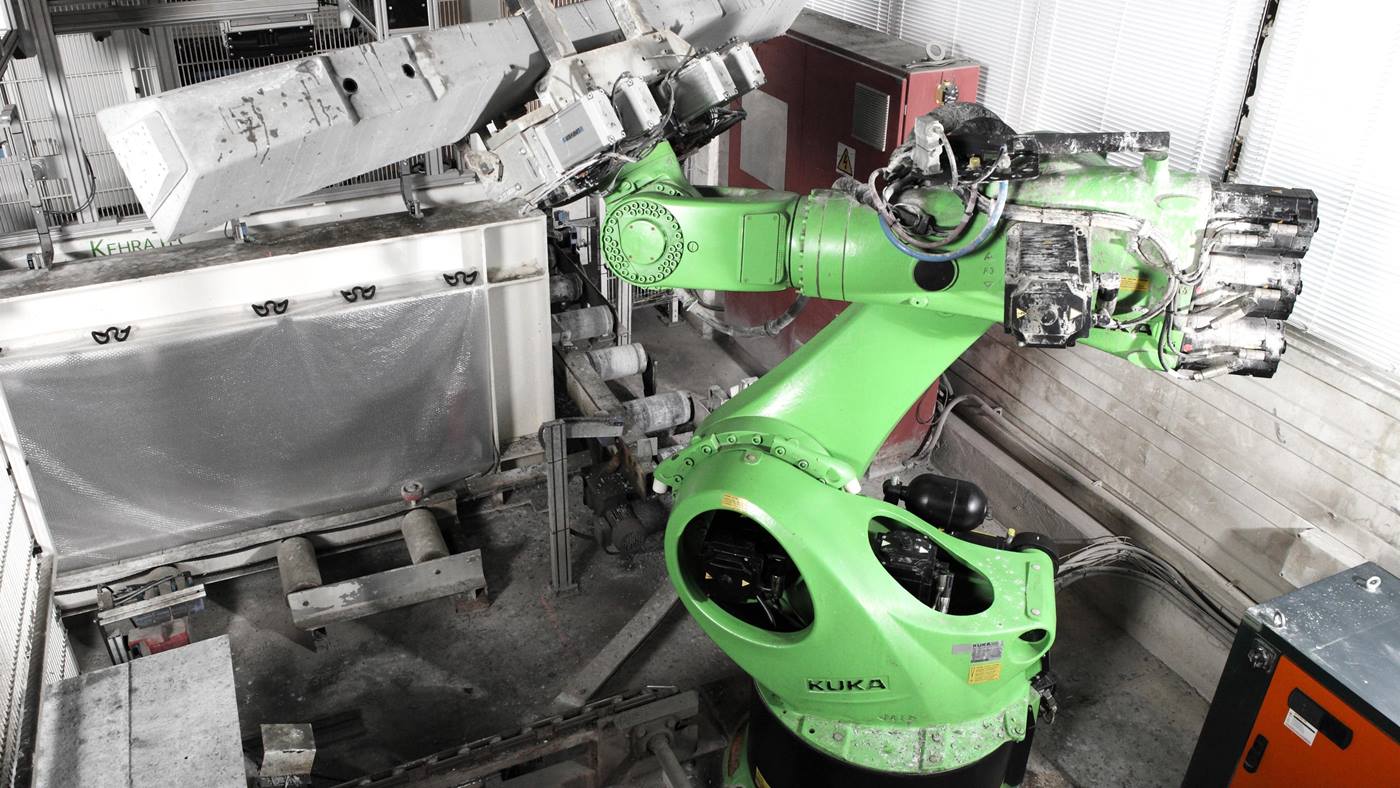

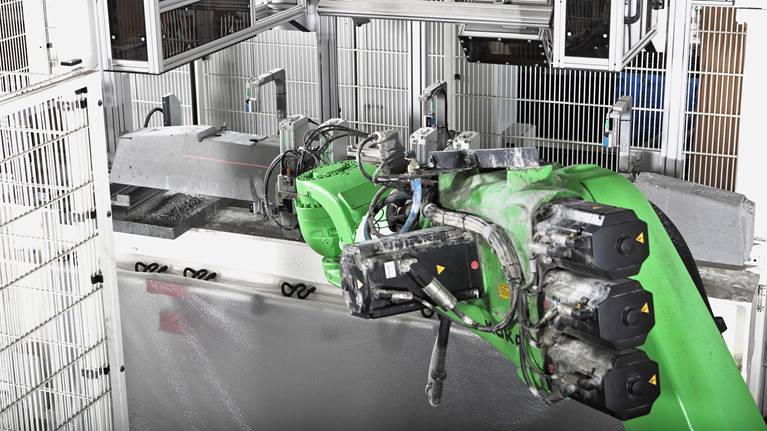

KR 500-3

KR 500-3

Through innovation, dynamism and continuous upgrading of process technologies, the company delivers a wide range of different options for process optimization to customers in the sanitary engineering, transport technology, medical and automotive industries.

Easier handling of railway sleepers

Located near Vienna, Maba Track Solutions GmbH – a Kirchdorfer group company – turned to KehraTec in search of a 100% solution for 3D measurement of the railway sleepers it manufactures. This entailed not only fully measuring the railway sleepers, but also finding a way to facilitate the handling of the sleepers weighing 320 kg and having a length of 2.60 m.

Sleepers weigh up to 320 kg

The concrete railway sleepers are first fed to the application in unmixed mode by means of a chain transfer. The system can be used to handle and measure up to seven different types of sleepers.

The largest and heaviest sleeper is 2.60 m long and weighs 320 kg. The KUKA robot picks up each concrete railway sleeper and turns it over by means of an overhead motion. This replaces the turning operation needed in one of the next production steps. Subsequently, the robot moves the railway sleeper into various positions for the KehraTec 2D and 3D vision system. Once the full KehraTec check has been conducted, the robot sets the railway sleeper down again and the cycle starts again from the beginning.