Weldeye for ALO3

Weldeye for ALO3

With over 400 Lessmüller Lasertechnik systems installed worldwide, external illumination based WELDEYE offers trend-setting solutions for seam-tracking and quality assurance. The smart WELDEYE quality system has been customized to complement Scansonic ALO3, supplying it with visualization and automated quality control functions for premium weld / braze quality.

Function description

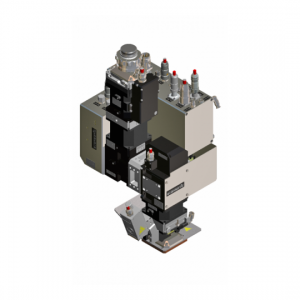

The integration of WELDEYE camera and illumination technology into the Scansonic ALO3 laser head (for magnifications 1.0, 1.1, 2.1., 3.3., 4.0, 5.2., 5.3.; for further magnifications on demand) creates the conditions for using all functions of the Lessmüller quality system. The combination of the dynamic WELDEYE camera AP 3.0 and the fourth generation illumination module with planar structured narrowband light source is a key technology for the visualization of the welding process area and its surrounding along the entire scanning range.

During the active welding process, the process light is optimally suppressed by a narrowband filter. 300 images per second are alternately recorded with and without external illumination. In no-illuminated images the intensity of the reflected process light is examined. Illuminated images reproduce the regions around the process beam with high resolution, in particular the cooled seam surface together with the distribution profile of the light reflected off the seam. The actual seam profile is generated from image to image and compared with the reference. The image processing signals serve for quality control purposes and automated online determination of weld faults.