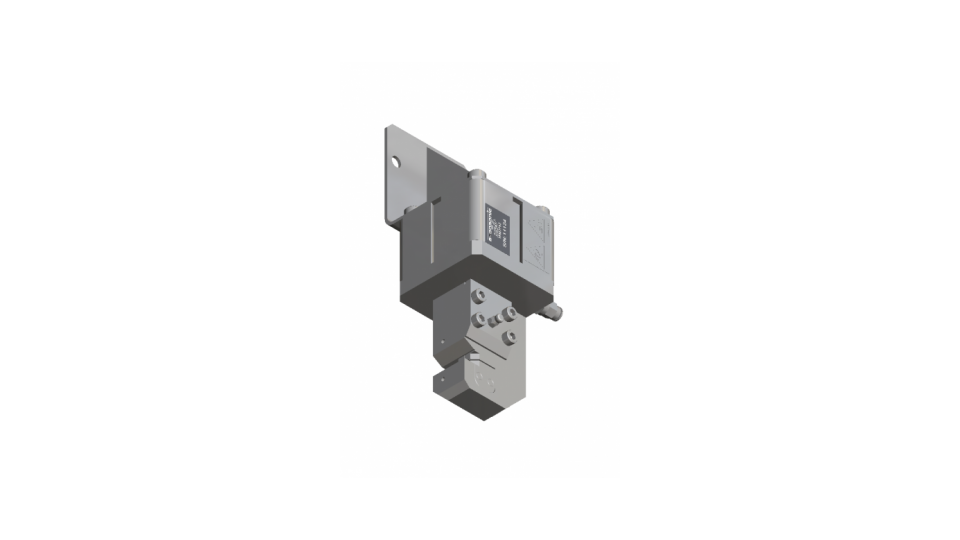

DAS 45°

DAS 45°

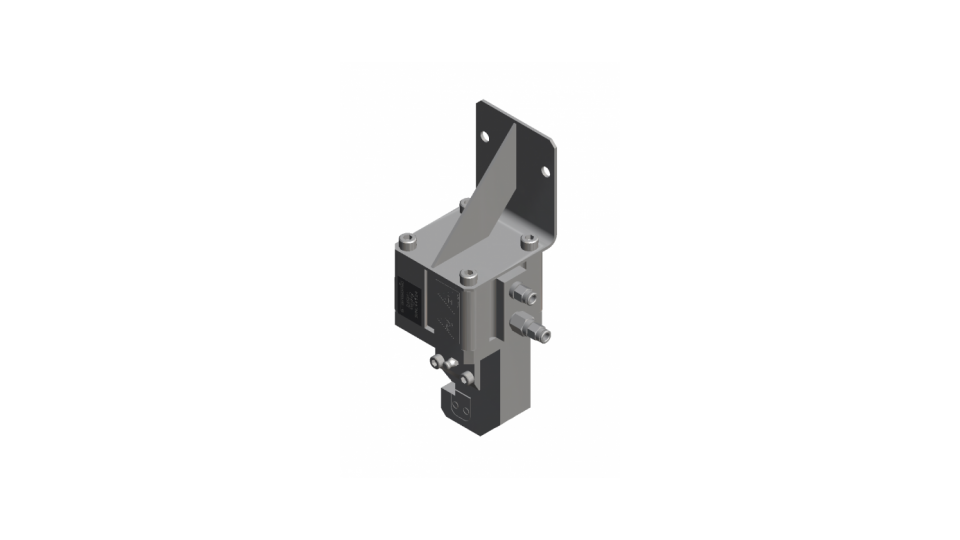

The DAS 45° wire cutter is optimized for seam tracking processes with filler wire. The system cuts filler wire at different angles with very short, predefined wire lengths.

Areas of application

- Laser brazing/welding with the ALO3

- – Electric arc processes with the APN1

Advantages

- Larger filler wire contact area for secure tactile probing on a weld butt joint with lower edge height

- No extension/retraction of the filler wire, required for small stick-outs

- This minimizes the need for programming/synchronizing with wire feed modules

- Integration into the safety check process by end position detection of the clamping die

Properties

- Easy accessibility to clamping die and cutting blades, no risk of collision with the processing tool

- Pre-tensioning of wire end eliminates kinking during cutting

- Variable cutting angle allows filler wire to be placed flat parallel to the component

- Minimum section length >4 mm

Optional

| End position sensor | monitoring of the clamping die position |

| 5/2 directional valve | to control the pneumatic cylinder |

| Telescopic sleeve and storage bin | for removal and storage of cuttings |

| Operating pressure | 6 Bar |

| Cutting performance at 6 bar | Solid wire up to 1.6 mm / Filler-wire up to 3.2 mm |

| Cutting time | approx. 0,5 sec |

| Power supply | 24 V DC actuator and control voltage |

| Weight | approx. 2,35 kg |