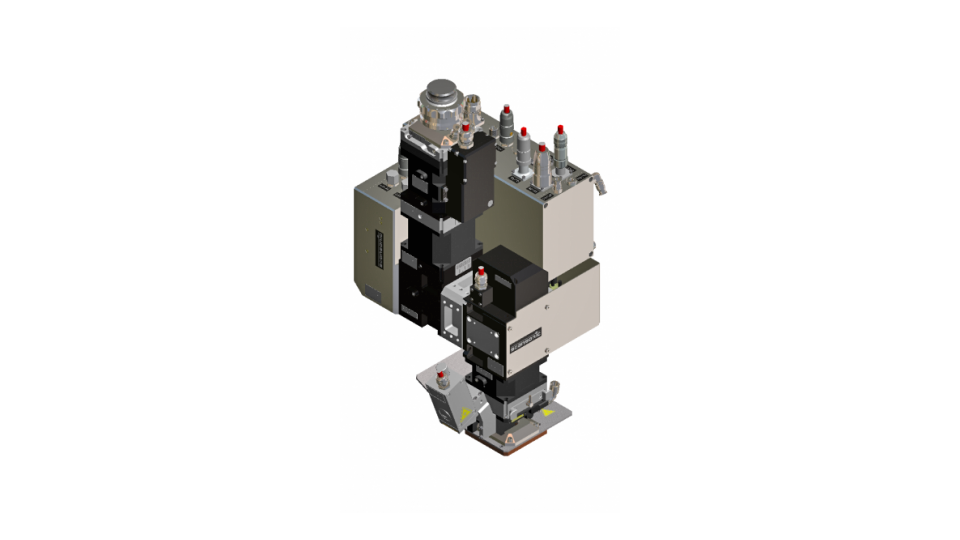

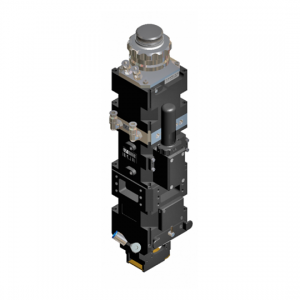

RLH-A

RLH-A

The RLH-A offers real advantages when it comes to remote laser hardening of intricate component structures. It enables process-reliable hardening depths in the 0.1-millimeter range along with a variable design of the spot geometry. Individual material surfaces can be hardened selectively with contour accuracy – all with a single processing optic. In the past, different optics with corresponding spot shapes were required for different components. Now, the RLH-A handles every hardening task.

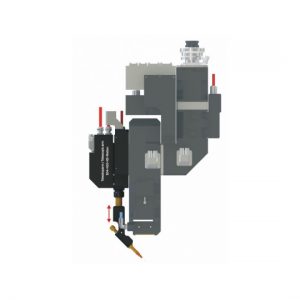

Function description

The RLH-A uses a highly dynamic 1-D scanning unit to create variable track widths. During the scanning motion, the temperature is recorded coaxially to the laser beam at the laser target location. The process temperature is then regulated according to the location by varying the laser power and scanning speed. The patented control circuit has a two-stage design to ensure maximum regulating speeds. This prevents melting of thin-walled components or edges. Thicker workpieces with higher heat capacity can also be sufficiently hardened.