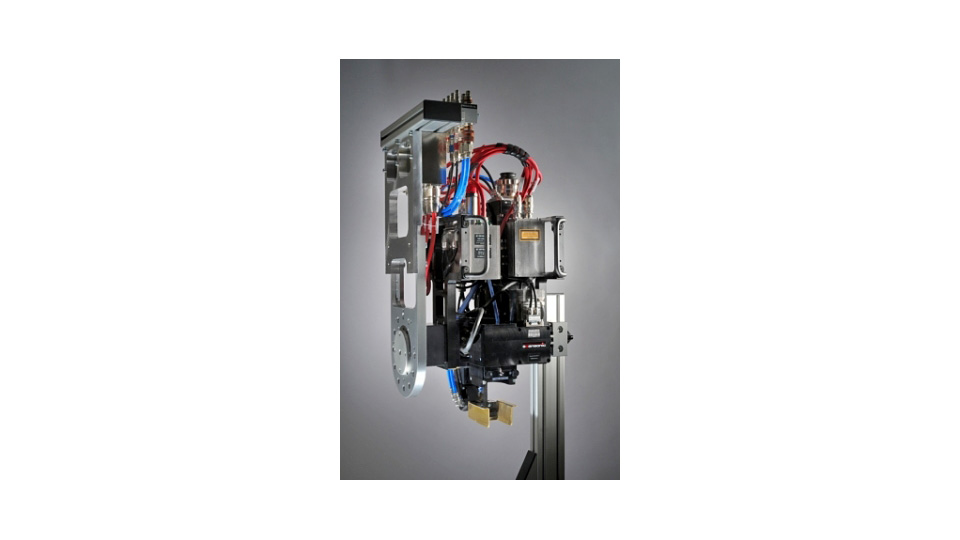

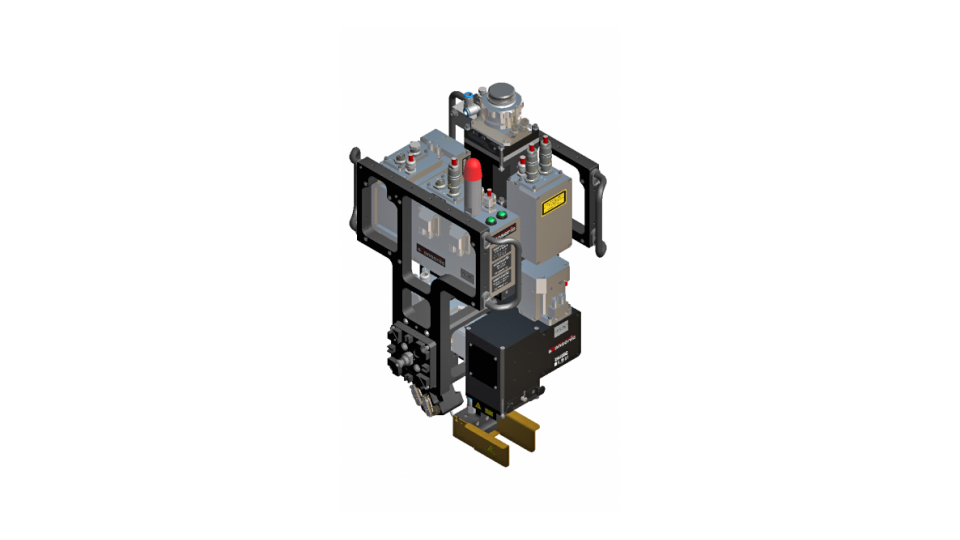

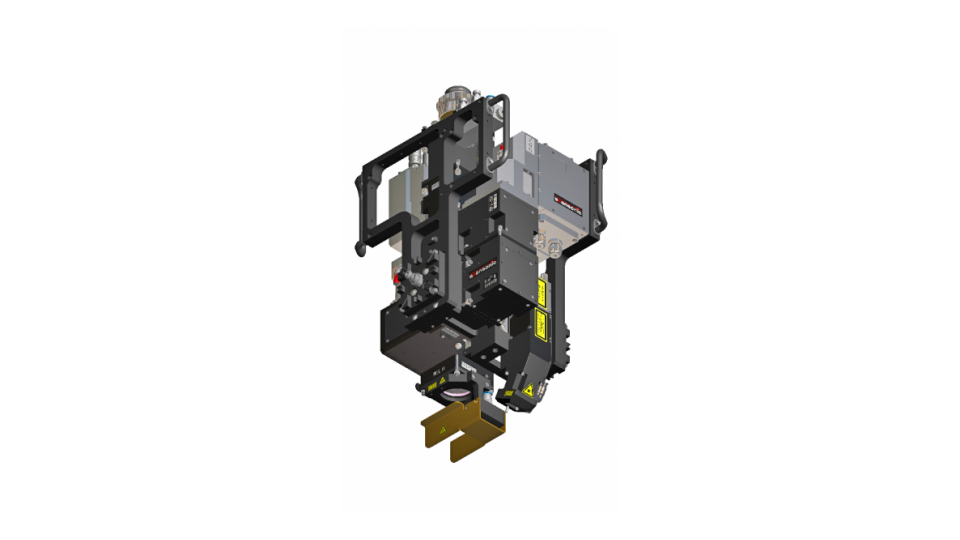

RLW-S

RLW-S

The RLW-S is ideal for the demanding task of welding of copper hairpins. This is made possible in part by the integrated camera sensor coaxially positioned to the laser beam. The sensor identifies the processing point even with different levels of reflectivity on the hairpin surfaces. It also ensures continuous process monitoring for high process reliability. This gives customers maximum dependability with strong, pore-free seams at high reproduction rates.

Function description

The RLW-S enables automatic recognition of patterns on the component as well as the position of the laser beam relative to the pattern contour. This makes it possible to define specific welding paths. A camera positioned coaxially to the laser beam detects the pattern layer(s). The movement of the laser beam is then calculated and executed via the path planning according to the parameterization. The deflection of the laser beam takes place via highly dynamic scanner axes and allows a positioning on the component along with a manipulation of the heat input via oscillation movements.