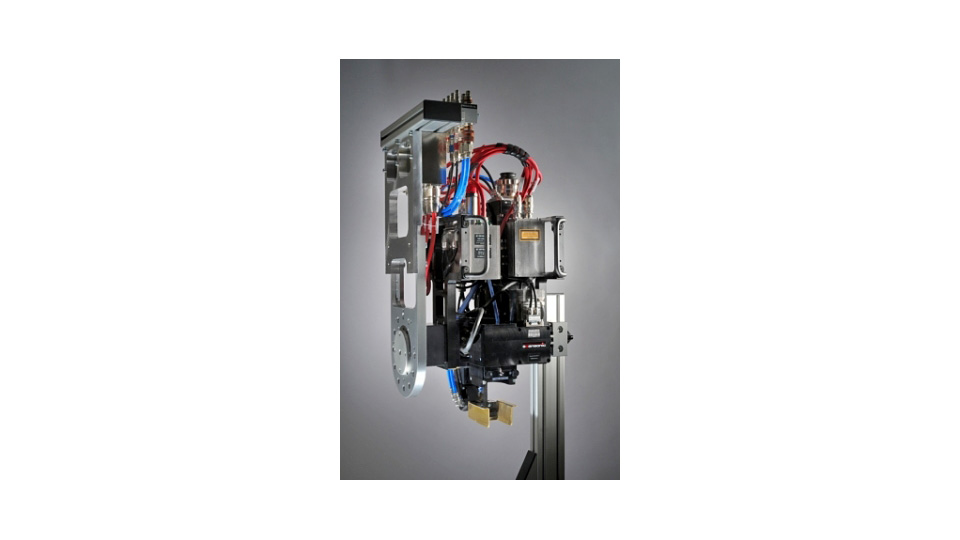

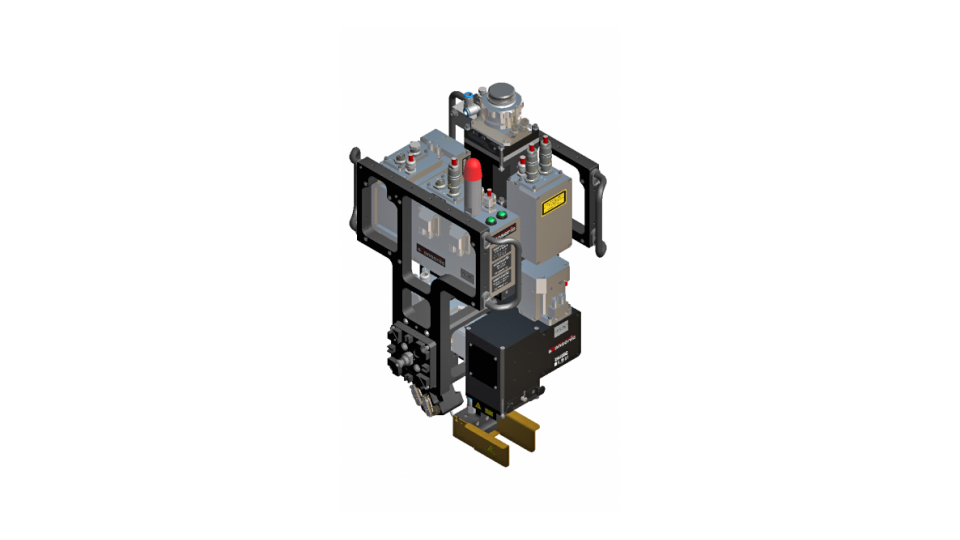

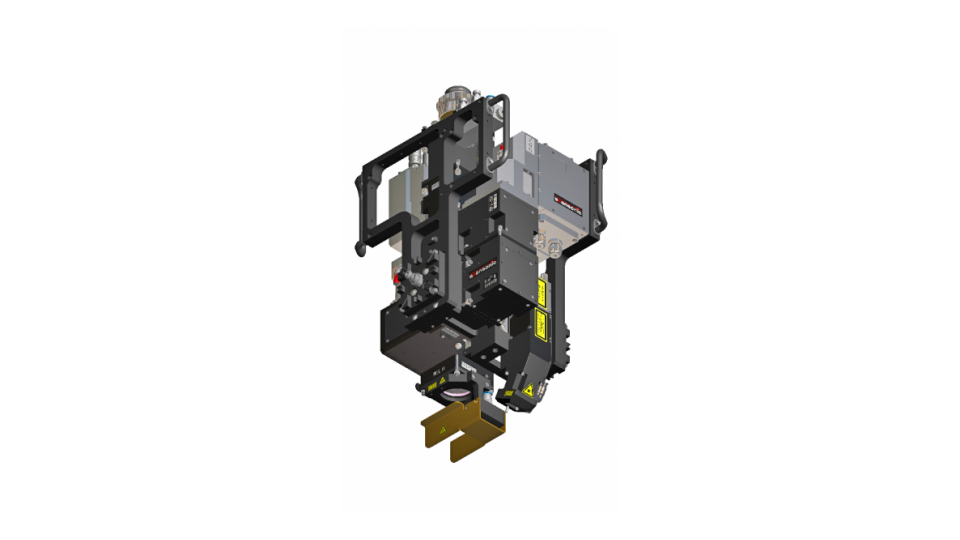

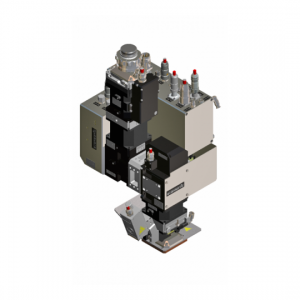

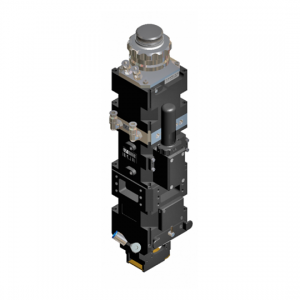

RLW-A

RLW-A

The RLW-A sets new standards in contactless fillet welding and enables overlap joints to be replaced by fillet welds. This reduces joint flanges and requires less laser energy for the same seam cross-section. The processing optics ensure precision, dynamics and reproducibility along with cost-effective operation.

Function description

The RLW-A system combines optical seam tracking with scanner axes. During the robot movement, the system measures the joint and controls the highly dynamic scanner levels online. Measuring precision is ensured by the patented coaxial guidance of laser beam and measurement light in the same optical system. The position of the laser spot remains precisely on the joint. This makes remote fillet welding possible on 3D body-in-white components.