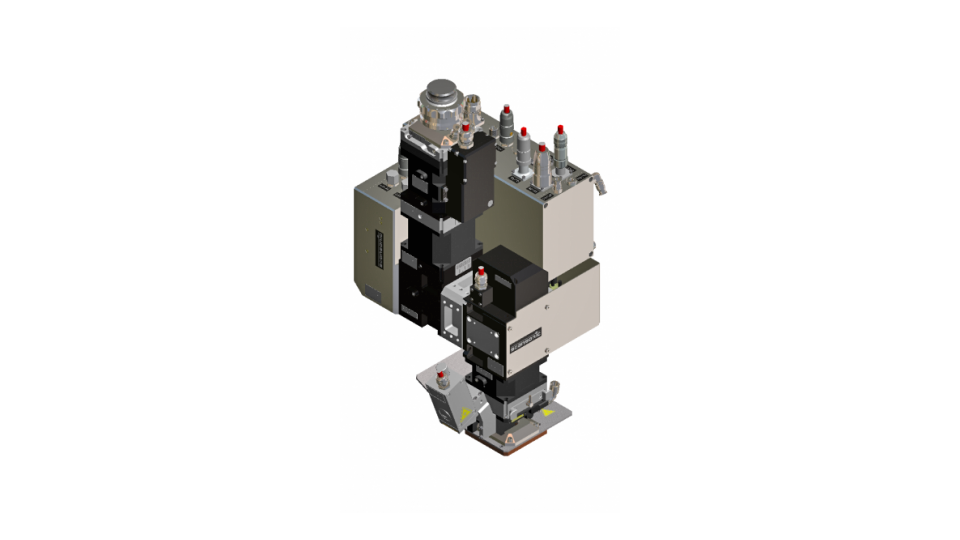

RLH-Basic

RLH-Basic

The RLH-A Basic is a cost-effective solution for hardening and softening surfaces. This versatile system features a built-in temperature control that enables a wide range of applications, from intricate contours to large and complex tasks.

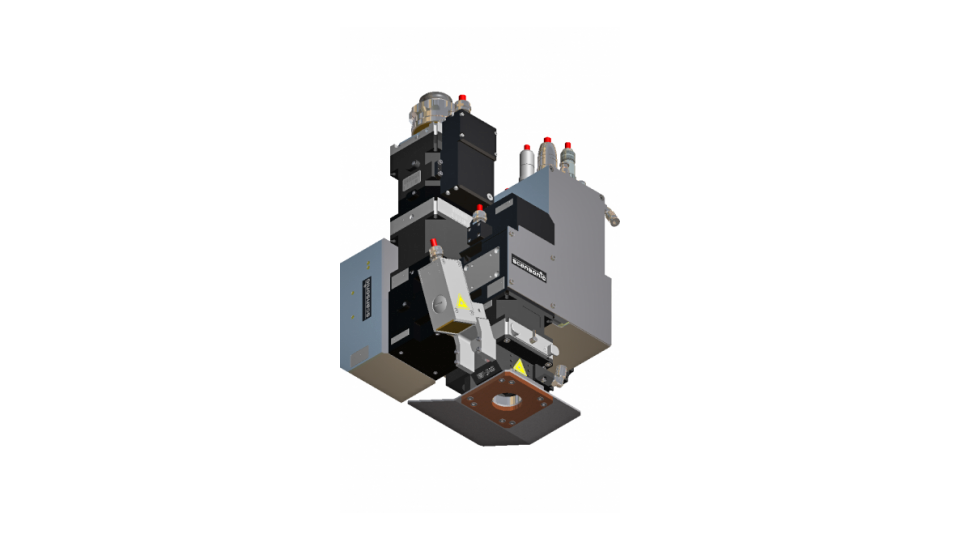

Function description

The process temperature is recorded coaxially to the laser beam at the laser target location and regulated by varying the laser power. This prevents melting of thin-walled components or edges. At the same time, thicker components with higher heat capacity can be sufficiently hardened.