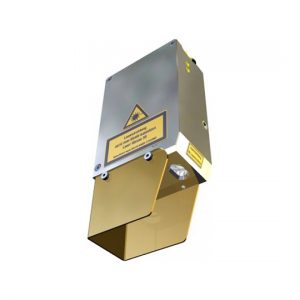

Model FH6D-150-KFAE

Model FH6D-150-KFAE

The FH6D is designed for optical seam tracking in automated welding

processes using an arc or laser. The sensor also supports the application of adhesives and other tracking processes. The seam tracking detects the position of the component and forwards the measured values to the tracking machine.

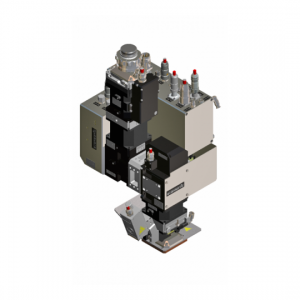

Function description

The triangulation sensor scans the seam shape along the joint without actually touching it and transmits information including gap dimensions, joint edge offset and positioning of the tool relative to the workpiece surface to the robot controller, for example, to correct the overall position of the component. Efficient signal analysis ensures reliable detection, especially on reflective surfaces.