ELEMENT 400

ELEMENT 400

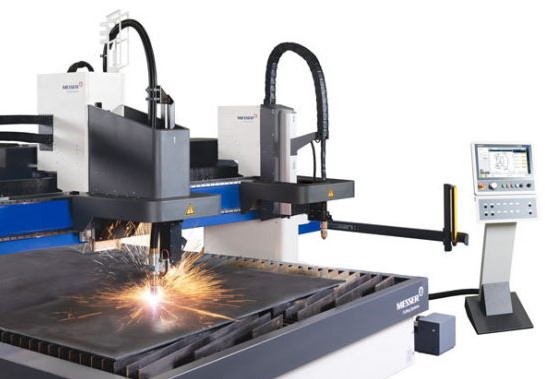

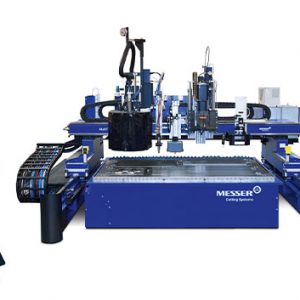

Element 400 cutting machine, the latest innovation from Messer Cutting Systems where form follows function. Included onboard is a new controller, the Global Connect, with redesigned HMI software and integrated OmniFab compatibility. This configuration features improved realtime transparency on maintenance, downtime status, and production reports that are transmitted through the controller, via a PC, or tablet. This machine can be equipped with many flexible options like plasma bevel cutting, oxyfuel cutting, marking, and cutting tables. Come see the new Delta Skew Plasma Rotating with cutting up to +/- 45 degrees, a high-acceleration drive with a C-axis ±460° rotation, for maximum production and efficiency.