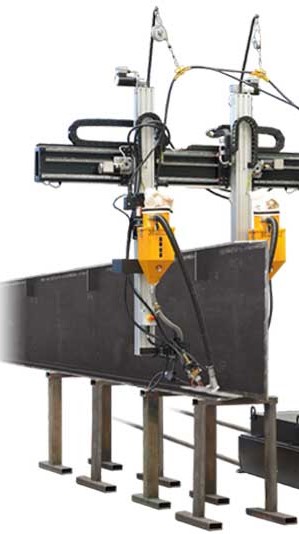

WA-1500 SAW Submerged Arc Welding System

WA-1500 SAW Submerged Arc Welding System

Automatic longitudinal top quality SAW welding of long structural Box beams and H, I, T. Single or multi-pass automatic fillet/butt welding with mechanical-electro joint tracking system. Significantly efficient production with improved weld quality.