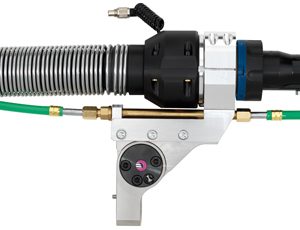

PUSH PULL PLUS 401D, LIQUID COOLED

PUSH PULL PLUS 401D, LIQUID COOLED

The perfect wire feed …

The welding torches of the Push-Pull Plus series, specially developed for aluminum welding requirements and the use of thin wires, makes problem-free and consistent wire feed and constant wire feed possible, even with longer cable assemblies. A powerful, sturdy pull motor with potentiometer guarantees exact speed regulation. For an optimum wire feed without frictional loss, the contact pressure of the feeding rollers can be regulated precisely and easily directly on the handle. The ergonomic handle ensures optimum, low-fatigue handling.

The screw-type torch necks can be replaced quickly.They are available as either straight or 45° angled versions. A special interface between the handle and the torch neck makes it possible to turn the necks up to 360°. All torches, both air and liquid-cooled for capacities of up to 400 A, are based on the tried-and-trusted “MB” torch neck design.

The main areas of application for these welding torches include wharfs, manufacturers of containers and ships etc., as well as in vehicle and wagon building. Wherever exact and constant wire feeding is an absolute must.