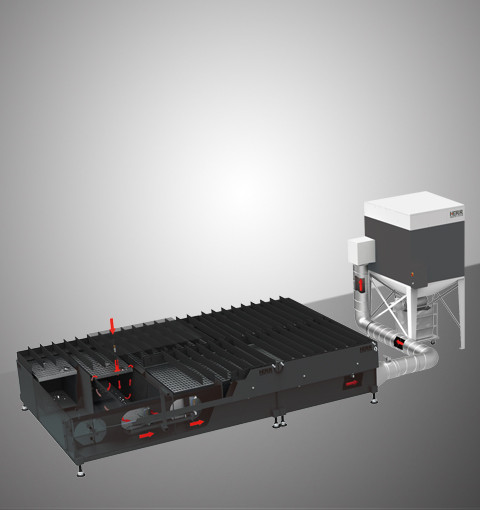

PLASVENT CUTTING TABLE

PLASVENT CUTTING TABLE

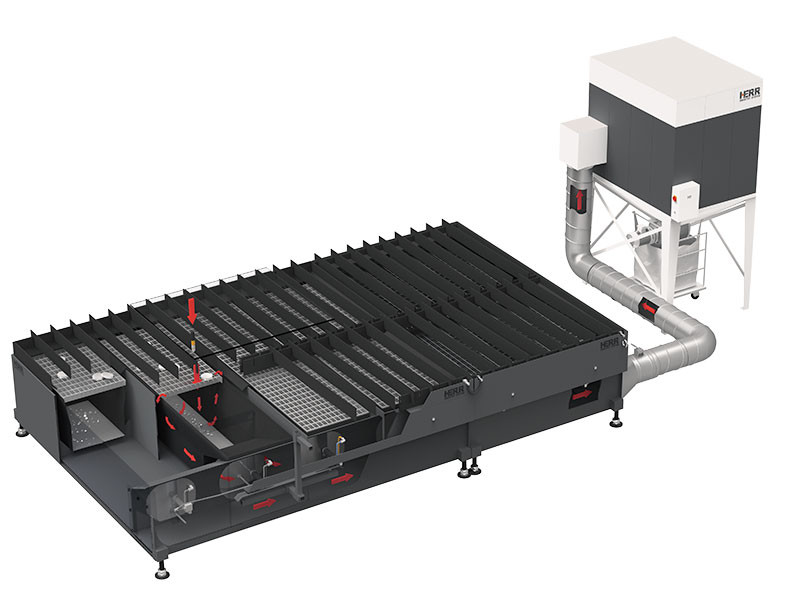

Besides the cutting machine in their entirety and the used material, the cutting table is responsible in major case for the quality of the cutted parts. It must therefore be worked sufficiently precise to achieve the desired quality. Moreover, the cutting table has to ensure effective and efficient removal of contaminated air.

Only in combination with a harmonized on the table and machine filter system and a suitable fan the desired effect, the effective protection of employees and machines, can be achieved. You receive from HERR a complete system consisting of table, filter system, fan and piping. Additional demands on a good cutting table are derived from ease of installation, further care and maintenance and also energy consumption.

PlasVent cutting tables from HERR are manufactured from high quality components and meet these demands. The tables are modular and can be adapted to local conditions. The modular design also allows easy transport and time-saving installation. The PlasVent cutting table needs low maintenance. Compressed air lines inside are made of copper and the longevity of the other materials used, effectively reduce follow-up costs in the form of repairs and spare parts.

The optimized exhaust duct, the design of the flaps and the massive construction reduce the need for compressed air and save energy.

The modular design of the cutting table fulfills almost all sizes requirements for cutting tables.