TH6D GF Standard

TH6D GF Standard

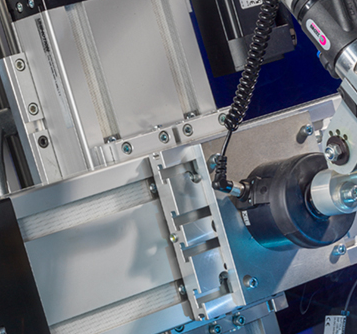

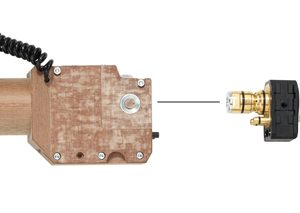

Simply press the start button and the welding task is carried out exactly – without any expensive robots … With the AutoGuide Plus, partially automated welding is guaranteed to succeed. This automatic torch guide with optical seam tracking sensor ensures that the welding torch welds where it is supposed to weld. If components have been prefabricated outside the tolerance or if the tolerance is too large, a programmed, automatically produced weld seam is quickly at a spot where it does not belong. The AutoGuide Plus 2-axis torch guidance system corrects the welding path in real time based on the seam tracking sensor TH6 data and makes constant observation of the welding process by an employee unnecessary. Even with reflective materials.

Significant cost savings in production

AutoGuide Plus is very easy to use with just a few simple selection menus. There is no need for time-consuming training of the operating personnel, programming knowledge is not required. Three positions are defined in advance and set on the device, as well as the sensor and the seam position to be searched. Press the start button and off you go. Monitoring by employees is no longer necessary, because the system works completely independently and corrects the torch position automatically. An employee can operate several welding processes with AutoGuide Plus at the same time and always gets the perfect weld. All in all, it increases efficiency, quantities and quality. Significantly!