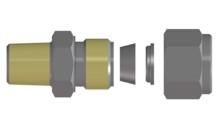

Spectropur Purge- and connection block SBE/3-MV3

Spectropur Purge- and connection block SBE/3-MV3

- Minimized purge volume of only 1,4 cm³

- The capillary tube allows purging into the cylinder valve

- Metal-to-metal seal to atmosphere using metal diaphragms made of Hastelloy C276

- All gas-wetted parts made of stainless steel SS 316L, Hastelloy C276, and PCTFE or PVDF respectively

- Fully functional even when valves are evacuated

- Minimum particle generation, as no parts are exposed to friction and no spring is in the gas wetted area

- Embedded soft seat seal made of PCTFE or PVDF permits frequent operation without loss of tightness

- Modular design for easy replacement of internal parts

- Clearly legible position indication (on/off)

- High surface quality

- 100 % Helium-leak-tested

- Assembly in cleanroom class ISO 5.0

- Approved for the use with oxygen up to 250 bar

- 2 versions: Inlet (gas cylinder) on the right or on the left side (process gas valve is always behind)

| Materials | |

| Body: | SS 1.4404 (SS 316L) |

| Diaphragms: | Hastelloy C276 |

| other gas wetted parts: | ES 1.4404 (SS 316L) |

| Valve seat seal: | PCTFE or PVDF |

| Surface roughness: | Rₐ ≤ 0,25 µm |

| Surface roughness (gas-wetted areas): | Rₐ ≤ 0,13 µm |

| Leak rate | |

| to atmosphere: | 1 x 10⁻⁹ mbar l/s He |

| via valve seat: | 1 x 10⁻⁶ mbar l/s He |

| Pressure range | |

| Manual valve: | max. 300 bar |

| Pneumatic valve: | max. 25 / 100 / 200 / 300 bar |

| Cv-value: | 0,13 (kv = 0,11) |

| Nominal size: | DN 3 |

| Gas cylinder valve connection | • acc. to DIN 477 depending on gas type • acc. to other standards (as BS, AFNOR, UNI) upon request |