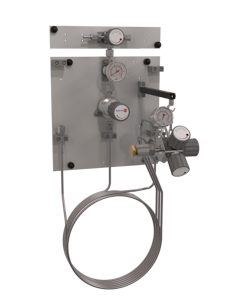

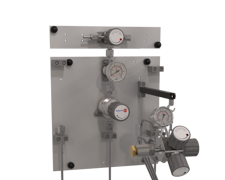

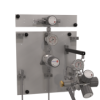

Spectropur Pressure control panel SP4-SBE

Spectropur Pressure control panel SP4-SBE

- Pressure control panel for flammable gases and ultra high purity gases from grade 6.0

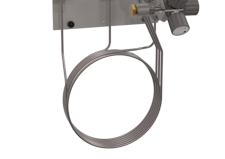

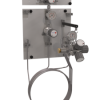

- SBE: purge- and connection block or SR: pigtail and single valves with – manual waste gas valve (HPV) – manual process gas valve (HPI) – manual purge gas valve (PGI)

- Check valve to prevent process gas from flowing back into the purge gas line

- Pre-filter

- Pressure regulator with tied diaphragm

- Burst disc

- Stainless steel valves for manual or automatic (pneumatic) shut-off

- Minimized purge volume (SBE)

- Electropolished surfaces (gas wetted)

- Clearly legible handwheel position indication (on/off)

- 100 % Helium leak tested

- Assembly in clean room class ISO 5.0

- Modular design with many options

| Operating pressure: | max. 300 bar |

| Materials | |

| Body: | Stainless steel 1.4404 |

| Diaphragms: | Hastelloy C276 |

| Other gas wetted parts: | Stainless steel 1.4404 |

| Sealings 51 (P1 ≤ 50 bar) or 2. stage 53: | PTFE |

| 51 (P1 > 50 bar) or 1. stage 53 and valves: | PCTFE or PVDF |

| Surface roughness (gas wetted areas) | Ra,max ≤ 0.25 μm |

| Surface roughness (gas wetted areas) | Ra,Avg ≤ 0.18 μm |

| Temperature range: | -20°C to +60°C |

| Leak rate to atmosphere: | ≤ 10-9 mbar l/s He |

| Leak rate via valve seat: | ≤ 10-6 mbar l/s He |

| cv-value: | cv = 0.24 (kv = 0.2) |

| Weight: | ca. 8 kg |

| Connectors | • Cylinder connection (process gas inlet) • VCR-female (waste gas, process gas outlet) • VCR-male (purge gas) |