SmartBlade

SmartBlade

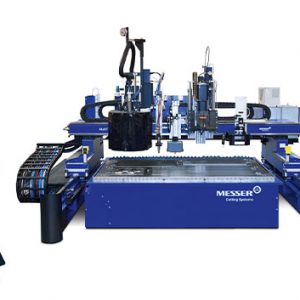

The SmartBlade has been conceived for use in small workshops with limited space available and offers all the advantages of a fully-fledged plasma cutting machine. The machine concept focusses on the operator and flexible working –the simple operation ensures for you the desired cut quality for all tasks. The SmartBlade is the economical entry level machine for everyone who demands the best quality even with complex vertical cuts.

Your customers need side walls for ventilation systems, cut parts for metal covers or holders, and that in the shortest time? With the plasma cutting machine SmartBlade you can fill such orders simply and quickly. The working width of 1.5 m and a working length of maximum 3 m open many possibilities for you. Plasma cutting up to 15 mm plate thickness on Mild Steel, Stainless Steel or Aluminium? The SmartBlade makes this easily possible. Thus it is cast in the ideal role for all requirements – from simple right up to complex vertical cuts.

The bridge and table form one unit, because of the good static characteristics, the plasma machine is not easily disturbed whilst cutting. And you can also rely quite relaxed on good quality cuts in the most varied materials. On top of this, your competitive edge is increased by the attractive purchase price and the low operating costs resulting from the long lasting and low maintenance components incorporated in the machine.

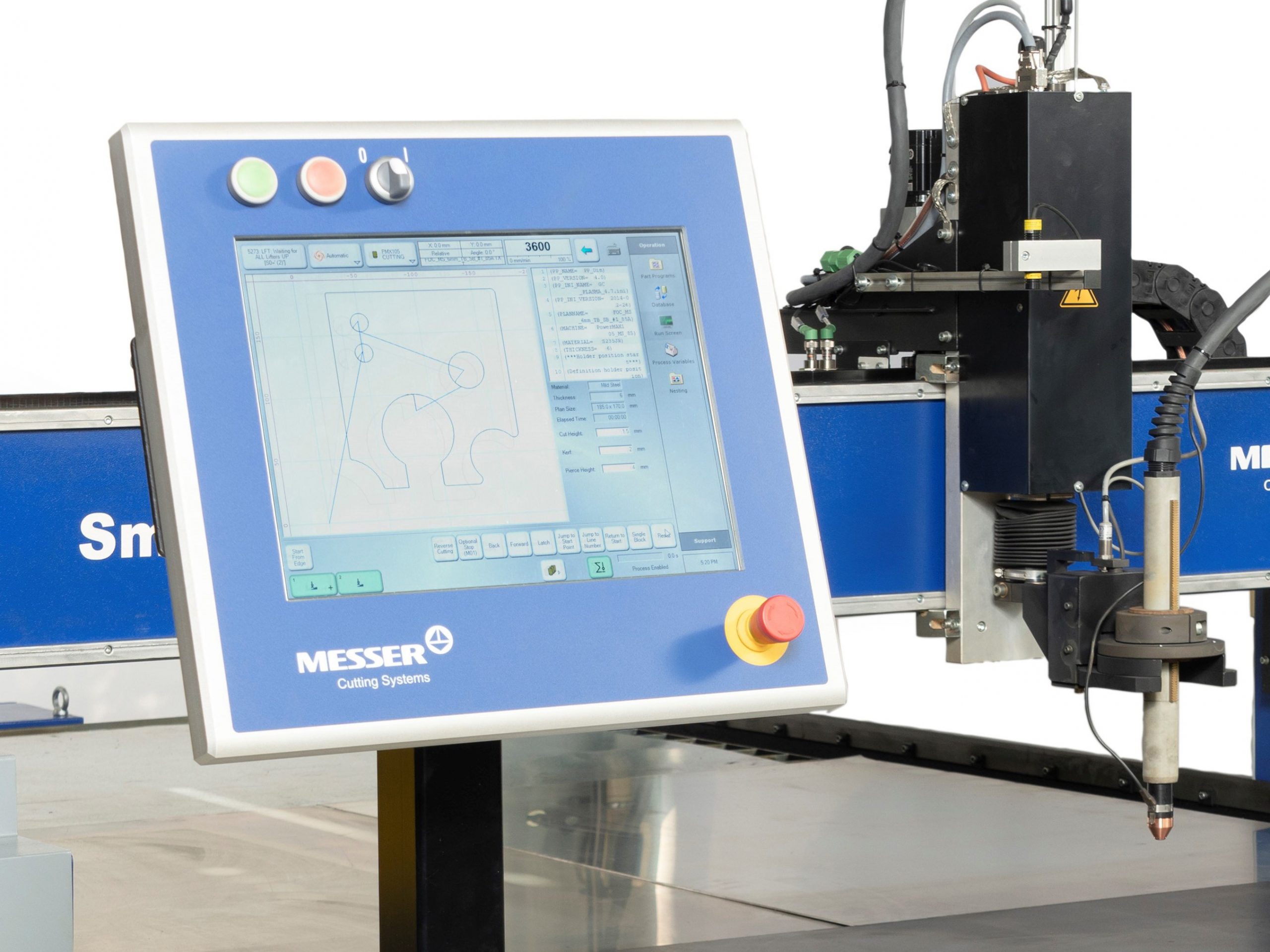

The SmartBlade meets the requirements of all Standards which you need for reliable production. Your plasma cutting machine should be easy to use? We have developed the CNC control system Global Control for this. With its graphical interface it simplifies the task of the operator enormously.