ROBO WH W 300 and ROBO WH-PP W 300 (liquid cooled)

ROBO WH W 300 and ROBO WH-PP W 300 (liquid cooled)

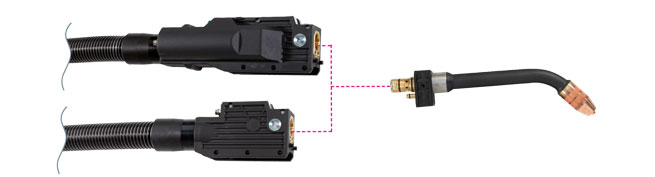

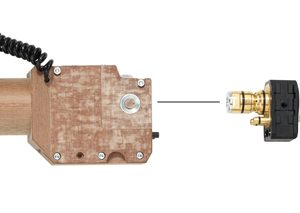

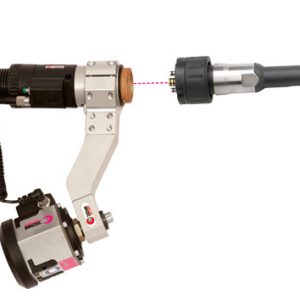

The liquid cooled MIG/MAG neck change welding torch system WH / WH-PP enables the complete torch neck to be replaced either manually or automatically – thanks to the innovative interface technology on the change body. This means torches of the same design can be replaced in seconds for maintenance purposes, or torches with special geometries for different welding positions can be changed as required.

Equally, the replacement of contact tip and gas nozzle and the monitoring of the TCP also takes place outside of the welding cell, thus increasing the availability of the system and reducing downtimes.