RLW-A

RLW-A

The reduction of CO2 emission is a matter of particular interest. To have a share to achieve these high aims, Scansonic developed an according production head, which allows the welding of fillet welds in a lap joint with the remote laser technique.

In the body in white production at present mainly overlap joints are deployed, which can be replaced by fillet welds. With fillet welds the necessary length of the flanges can be reduced, the process is stable without preliminary steps and less laser energy for the same seam cross section is needed.

How it works

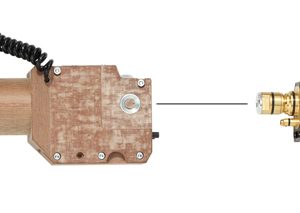

An optical seam tracking which is integrated in the welding head recognizes the joint and is positioning the laser focus on the join patch. Due to the high working distance is the head able to pass over spanner and work piece contours. The necessary process time is much reduced in comparison to tactile systems and slightly higher regarding standard laser remote heads.

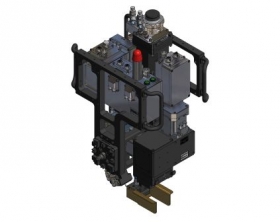

The RLW-A laser system combines optical seam tracking and high dynamic scanners. That enables the usage of difficult 3D geometries with a wide range of joint types. Dureing the robot movement the RLW-A detects and follows the seam by adjusting the mirror according to the measurement data of the seam tracking. The laser beam and the measurement light are controlled by the same optical system.