Rail Bull 2 – All Position Welding Tractor

Rail Bull 2 – All Position Welding Tractor

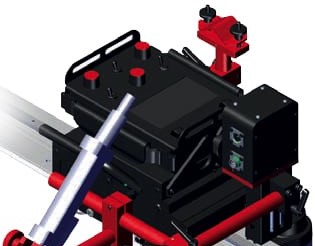

Automated welding and cutting tractor – Rail Bull 2 can be custom configured for a variety of welding, thermal cutting and gouging applications on flat or curved plate, tube and pipe. It’s suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials. Rail bull 2 is best choice for your cutting and welding automation process.

- Fully modular mechanized travel tractor can be custom configured for a variety of welding, thermal cutting and gouging applications on flat or curved plate, tube and pipe

- Linear torch oscillator to produce weave welds

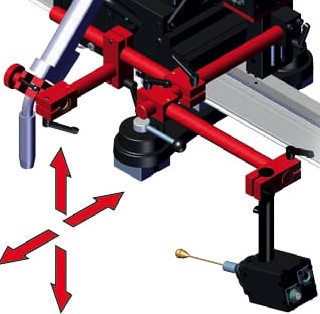

- Active compensation of torch position vertically and horizontally by means of modular automatic seam tracking system

- Programmable path of stitch welds

- Possibility to select one limit switch preset out of three presets available.

- Suitable for variety of circumferential and irregular surface applications down to minimum radius of 100 mm (4”)

- Ring tracks on diameters from 200 mm (8”) OD up to 3 m (10 ft) OD

- Hi-Flex tracks on diameters from 1500 mm (59”) OD upwards

- Custom rolled tracks on diameters from 3 m (10 ft) OD up to 10 m (32 ft) OD

- Semi-flexible tracks can be flexed to minimum radius of 5 m (16 ft) without permanent deformation

- Ergonomic remote control pendant with simple and easy to find control knobs makes adjustments possible without lifting of the operators welding hood

- Magnetic adhesion of the pendant provides firm grip on ferromagnetic materials

- Suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials thanks to rack and pinion drive and various tracks equipped with magnetic or vacuum units

- Rail Bull 2 produces consistent high quality welds and cuts in a fraction of the time required by manual operations

- High speed up to 3 m/min makes plasma cutting available

| Voltage: | 1~230 V, 50–60 Hz

1~115 V, 50–60 Hz

1~ 42 V, 50–60 Hz |

| Power: | 120 W |

| Welding position (according to EN ISO 6947 and AWS/ASME): | PA / 1F / 1G

PB / 2F

PC / 2G

PD / 4F

PE / 4G PF / 3G PG / 3F (contact your dealer) PG / 3G |

| Fixing on pipes and round – Ring tracks workpieces: | from 200 mm (8”) OD up to 3 m (10ft) OD |

| Fixing on pipes and round – Hi-flex tracks: | Minimum curvature radius of 750 mm (30”) |

| Fixing on pipes and round workpieces – Custom rolled tracks: | rom 3 m (10 ft) OD up to 10 m (32 ft) OD |

| Fixing on pipes and round workpieces – Semi-flexible track: | Minimum curvature radius of 5 m (16 ft) |

Torch type: | MIG/MAG, TIG, Plasma, Oxy-fuel |

Torch diameter: | 16–22 mm (0,63–0,87’’)

fino a 35 mm (1,38”) opzionale |

Horizontal pulling force: | 400 N |

| Vertical pulling force: | 300 N |

Horizontal speed: | 0–300 cm/min (0–120 in/min) |

Vertical speed: | 0–300 cm/min (0–120 in/min) |

Oscillation type: | Linear |

Weld path: | Straight, triangle, trapezoid, square |

Oscillation width: | 0.2–11.8 cm (0.1–4.5’’) |

Oscillation speed: | 10–300 cm/min (5–120 in/min) |

Oscillation dwell time at center and on ends: | 0–5 s |

Weight: | 10 kg (22 lbs) |