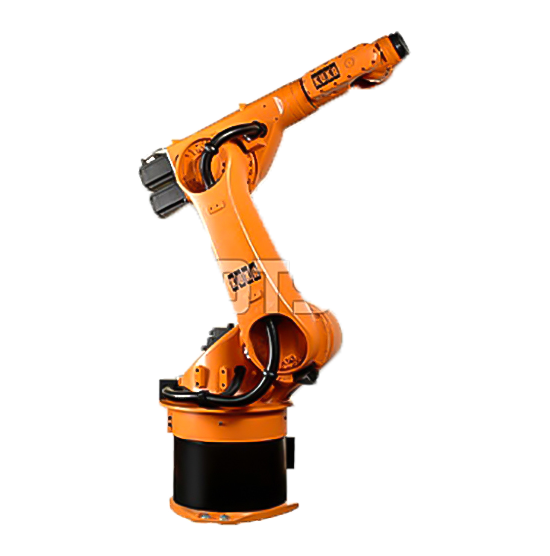

KUKA KR 30

KUKA KR 30

The highly flexible and durable KUKA KR 30 handles diverse applications. Its modular design allows for simple payload and reach modifications. With a small footprint and variable mounting options, the KR 30 KR C2 fits the bill for space-efficiency and versatility. The KR 30 KR C2 robot is easily customized for different projects and requirements. It is capable of low to medium payloads, and powerful, accurate movement.

The KR 30 JET robot system is also available. This robot is light weight and extremely fast. It has a linear axis, jointed-arm and JET TRACK axis module that helps to free up valuable floor space. The robot knee can be mounted overhead or on the wall, providing optimum axial symmetry to ensure the robot’s reach, deep into machines.

The modular structure of the KR 30 JET enables execution of the individual user and task-specific program sequences. Up to two robots can be deployed on the JET traversing axis, making it possible to tend several machines or positions at the same time to further optimize the production process.

There is a wide range of gantry variants and a specially adapted linear unit to ensure speed and workspace are maximized. This system can be easily adapted to your current needs because of the overhead or side mounting options. The KR 30 JET has a 0.07 mm repeatability, a 1682.5 mm reach, and can cover distances of up to 30 meters. It can take parts out of machines from above with speed, precision, and high repeatability.