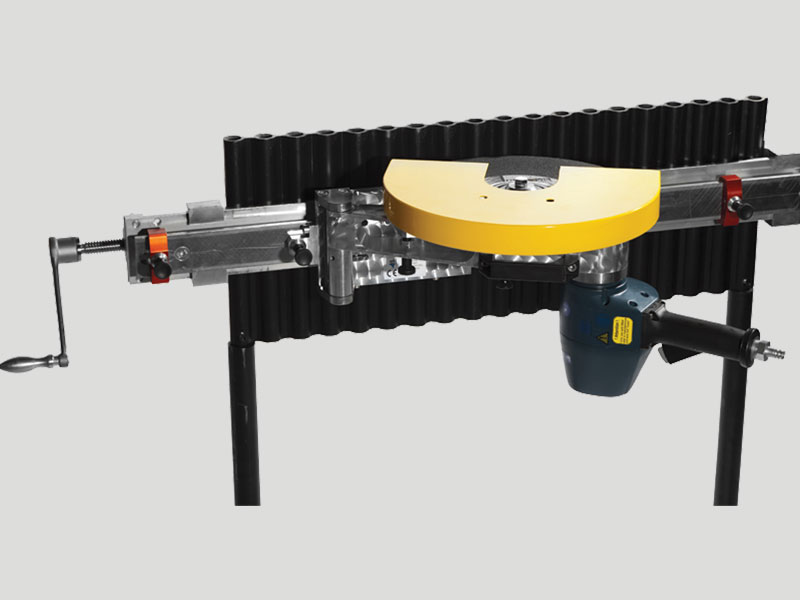

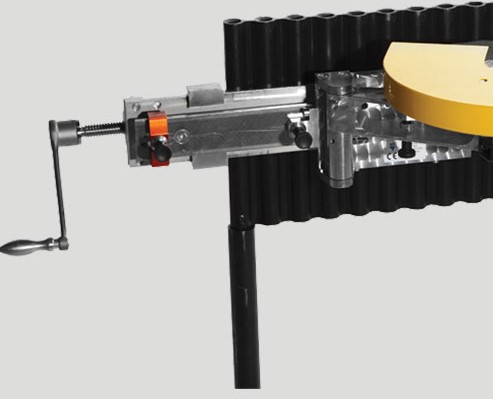

Boiler panel sawing system for waterwall panels

Boiler panel sawing system for waterwall panels

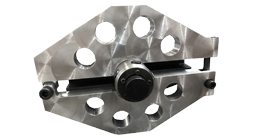

In maintenance of industrial high pressure steam boilers panel wall cold cutting is an important step before weld preparations. To avoid any heat affected zone (HAZ) on the boiler tubes of the water wall panels, the sawing of the defective panel wall tubes should be done not by flame cutting but instead with the BWC cutting system, that uses abrasive saws. The system increases safety of workers and works with high productivity. Due to the straight cut you will have less wearing of cutting discs and caused by the high cutting quality you have less after work, after removing boiler tube failures.