ALO3

ALO3

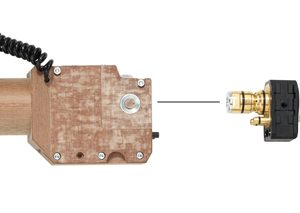

The ALO (adaptive laser optic) as a laser processing head ALO3 with integrated seam tracking by means of filler wire is now available for CW-Laser in the range of 880 -1070 nm.

How does it work?

The patented tactile seam tracking process allows the ALO3 to find the beginning of seam accurately and to guide the process precisely along the seam. Thereby the component allowances are automatically balanced. The independent system with seam tracking can be integrated in every guiding machine and will be controlled by digital In-/Outputs or Interbus.