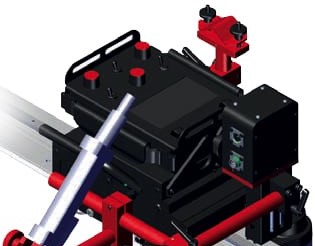

Rail Bull 2 – All Position Welding Tractor

Rail Bull 2 – All Position Welding Tractor

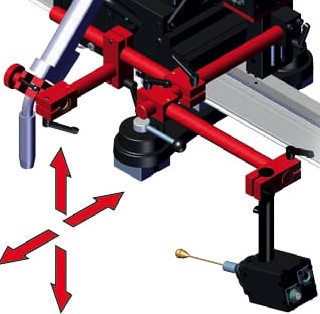

Automated welding and cutting tractor – Rail Bull 2 can be custom configured for a variety of welding, thermal cutting and gouging applications on flat or curved plate, tube and pipe. It’s suitable for all welding positions on both ferromagnetic and non-ferromagnetic materials. Rail bull 2 is best choice for your cutting and welding automation process.