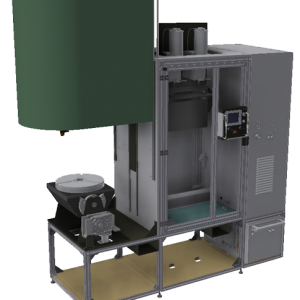

PSW 500 TL

PSW 500 TL

The plasma point welding device is used for sheet metal up to 2.5mm (PSW 350TL) or 3.5mm (PSW 500TL).

- Power source with HF-ignition

- Touch Screen 5,4″

- USB interface

- Ethernet interface

- Integrated welding program memory

- Integrated cooling

- Integrated monitoring / gaging of cooling medium

- Integrated electronic gas regulation (PGR)

- Integrated control of wire feeder / powder feeder (MCC)

- Integrated control of wire feeder / powder feeder (MCU-M)

- Integrated control of wire feeder and free wheel encoder (MCU-MI)

- Integrated control of 2 wire feeders and free wheel encoder (MCU-MSI)

- Integrated automation interface

- Software for external controlling via computer (diagnostics, parameter setup, documentation)

- Mobility by wheels

- Parking area for 20l gas bottle

- Flowmeter shielding gas

- Flowmeter plasma gas

- Remote Control RC-S

- HPP1 – High Pressure Pump (1 circuit)

- HPP2 – High Pressure Pump (2 circuits)

- Plate Heat Exchanger

| Applicable Welding Methods: | PLASMA Spot Welding |

| Range of suitable material thickness (Plasma spot welding): | ~ 0.5 – 4 mm |

| Automation | Capable for automation |

| Operating modes: | DC |

| Supply Voltage: | 3 × 400 V ±15 % 50/60Hz |

| Phase: | 3 Phase |

| Power connection: | 4 × 32 A CCE plug, 6 mm² |

| Adjustment range welding current: | 5 – 500 A |

| Adjustment range TIG mode: | 5 – 500 A |

| Adjustment range MMA mode: | 5 – 450 A |

| Cooling: | Liquid |

| Degree of protection: | IP 21 S |

| Length: | 1120 mm |

| Width: | 450 mm |

| Height: | 935 mm |

| Weight: | 112 kg |

| Automation Interface “Tiny”: | Included |

| Digital Inputs: | 2 × 24 V |

| Digital Outputs: | 3 × 24 V |

| Analog Inputs: | 2 × 0 – 10 V |

| Analog Outputs: | 2 × 0 – 5 V |

| CAN Bus (SBI protocol): | Included |

| Automation Interface “AS/AD Basic”: | Included |

| Digital Inputs: | 10 |

| Digital Outputs: | 10 |

| Analog Inputs: | 4 |

| Analog Outputs: | 4 |

| KTY Input: | 1 |

| CAN Interface: | Included |

| Connection cable: | 5m |

| Capability for / availability of specific bus interfaces: | Included |