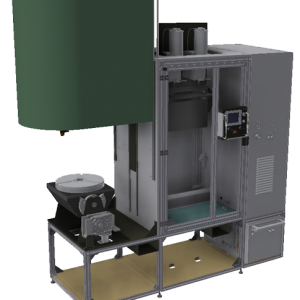

PMI 350 AC/DC TL

PMI 350 AC/DC TL

The AC / DC welding device is used for joint and build-up welding. In addition to steel, nickel, titanium, zirconium and copper, weldable materials are also aluminum alloys. With the plasma taphole process, it is possible to weld in one layer without processing edges, material thicknesses of up to 12mm.

- Power source with HF-ignition

- Pilotinverter with HF-ignition

- Touch Screen 5,4″

- USB interface

- Ethernet interface

- Integrated cooling

- Integrated welding program memory

- Integrated monitoring / gaging of cooling medium

- Integrated electronic gas regulation (PGR)

- Integrated control of wire feeder / powder feeder (MCC)

- Integrated control of wire feeder / powder feeder (MCU-M)

- Integrated control of wire feeder and free wheel encoder (MCU-MI)

- Integrated control of 2 wire feeders and free wheel encoder (MCU-MSI)

- Integrated automation interface

- Software for external controlling via computer (diagnostics, parameter setup, documentation)

- Flowmeter plasma gas

- Flowmeter shielding gas

- Parking area for 20l gas bottle

- Mobility by wheels

- Foot control of the current

- Remote Control RC-S

- HPP1 – High Pressure Pump (1 circuit)

- HPP2 – High Pressure Pump (2 circuits)

- Plate Heat Exchanger

| Applicable Welding Methods: | PLASMA Seam Welding PLASMA Brazing PLASMA Keyhole Welding |

| Range of suitable material thickness (Plasma seam welding): | ~ 0.5 – 8 mm |

| Range of suitable material thickness (Plasma spot welding): | ~ 0.5 – 3 mm |

| Automation | Capable for automation |

| Operating modes: | AC or DC or AC/DC Mix (for Al welding) |

| Supply Voltage: | 3 × 400 V-460 V ±15 % 50/60Hz |

| Phase: | 3 Phase |

| Power connection: | 4 × 32 A CCE plug, 6 mm² |

| Max. welding current at 35 % PMI50; duty cycle (40 °C): | 350 A |

| Max. welding current at 100 % duty cycle (40 °C): | 290 A |

| Adjustment range welding current: | 3 – 350 A |

| Max. pilot current at 35 % duty cycle (40 °C): | 50 A |

| Max. pilot current at 100 % duty cycle (40 °C): | 30 A |

| Adjustment range pilot current: | 0.5 – 50 A |

| Adjustment range TIG mode: | 3 – 350 A |

| Cooling: | Liquid |

| Degree of protection: | IP 21 S |

| Length: | 1120 mm |

| Width: | 450 mm |

| Height: | 935 mm |

| Weight: | 115 kg |

| Automation Interface “Tiny”: | Included |

| Digital Inputs: | 2 × 24 V |

| Digital Outputs: | 3 × 24 V |

| Analog Inputs: | 2 × 0 – 10 V |

| Analog Outputs: | 2 × 0 – 10 V |

| CAN Bus (SBI protocol): | Included |

| Automation Interface “AS/AD Basic”: | Included |

| Digital Inputs: | 10 |

| Digital Outputs: | 10 |

| Analog Inputs: | 4 |

| Analog Outputs: | 4 |

| KTY Input: | 1 |

| CAN Interface: | Included |

| Connection cable: | 5m |

| Capability for / availability of specific bus interfaces: | Included |