CENTRAL CARTRIDGE EXHAUST SYSTEM 600 SERIES

CENTRAL CARTRIDGE EXHAUST SYSTEM 600 SERIES

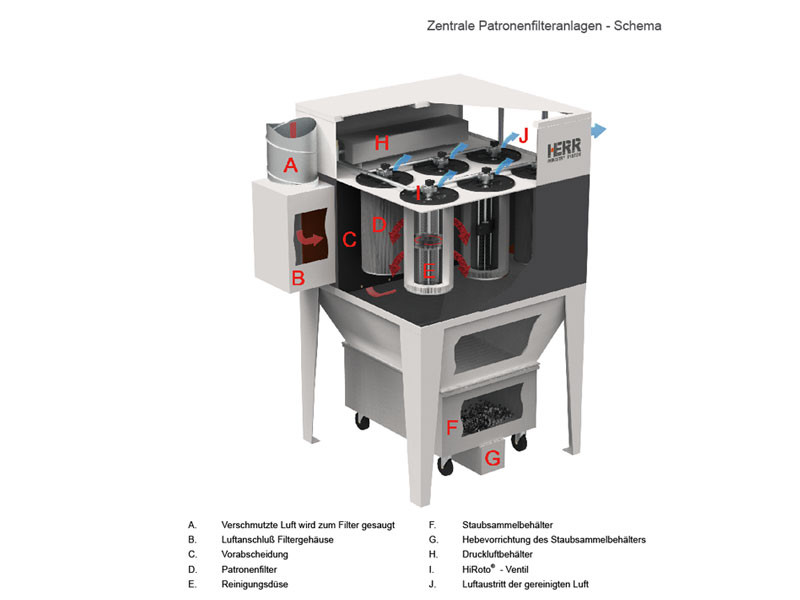

Filter systems of the 600 series are compact and ideal for grinding, welding and cutting applications which produce light to medium amounts of dust. The fan is integrated in the upper part of the filter unit. This arrangement produces a small footprint. When entering the filter sparks and large particles are separated from the fine dust and smoke. The pre cleaned contaminated air is then sucked through the filter cartridges, the particles hereby stick to the filter surface. The Siemens® logic monitors the work procedure and initiates the cleaning when the filter cartridges are stuffed. Cleaning is executed only when necessary – this saves energy and increases the filter cartridge lifespan.

The 600 series filter uses multiples of 10m² surface HISTec® ePTFE cartridges. The soft, quiet and efficient cleaning via the HiRoto® rotary nozzles saves air (energy) and stresses the filter cartridge less than conventional cleaning procedures via air pulse. The 6000 filter systems are designed to be used inside the workshop and available up to a capacity of 9,000m³/h. Optionally series 600 filter systems can be equipped with a frequency inverter to adjust the airflow according to the production needs. This saves energy and money.