Automated deburring of aluminium components with KUKA’s KR AGILUS KR6 R900

Automated deburring of aluminium components with KUKA’s KR AGILUS KR6 R900

A KR AGILUS robot was successfully installed by Manders Automation at aluminium specialist ALUMERO FINEX Extrusions. The robot can work at different speed levels and from different angles and starting points. It ensures that every product is deburred accurately – and this at a considerable speed.

Specialist for tailor-made aluminium solutions focuses on quality

The family business ALUMERO FINEX Extrusions B.V. from Helmond, Netherlands, is part of the Austrian Alumero Group. With more than 25 years of experience Alumero is a specialist in the aluminium market. FINEX focuses on specific aluminium precision of microprofiles with minimal tolerances and thin wall thicknesses. “We do not believe in standard solutions. Each customer has its own requirements and therefore tailor-made solutions are worked out for and, above all, together with the customer. For us, quality and service are just as important as quantity,” says Jeroen van Bussel, Managing Director at ALUMERO FINEX Extrusions.

Automation solution with KUKA robot increases productivity and ensures quality

One of FINEX’s customers is Secrid, a Dutch company that focuses on pocketware and develops distinctive cardholders and wallets. This company has a decorative product with a unique Dutch-Made, A-Product market positioning and a strongly cohesive supply chain. For Secrid it is extremely important that the aluminium end profiles are completely measured, unique and high-quality deburred. “The demand for pocket ware is increasing and as this is an A-brand, maintaining the quality is extremely important, regardless of the volume,” says Jerome van Bussel. In order to guarantee the same high quality at a higher volume, FINEX had to automate its production.

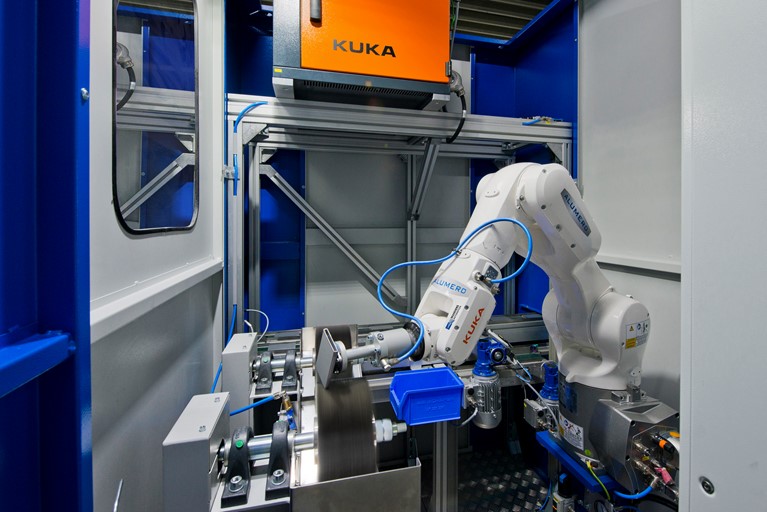

Flexible deburring cell with KUKA robot cuts the aluminum profile to the desired dimensions

At FINEX it was decided to have a specialized sawing machine and subsequent deburring cells with KUKA robots designed and installed by Manders Automation. This deburring cell contains a KR6 R900 AGILUS robot on which a vacuum cup is mounted. The robot works at different speed levels at different defined angles and starting points. The big advantage of the KUKA robot is that it has been programmed by FINEX and Manders Automation in such a way that it can also be adapted per profile and per robot cell according to the different customer needs.

Automation guarantees consistently high product quality

The sawing machine saws the aluminium profile to the desired dimensions and via a conveyor belt this profile is then placed in the robot cell. The robot picks up the profile and ensures that both the inside and outside contours are carefully finished. After this, the robot places the profile again on the conveyor belt that brings them to the next stop. This production automation was necessary because FINEX always goes to great lengths to meet the needs of its customers. Thanks to the automation, FINEX is now able to increase its production capacity without having to sacrifice the quality; on the contrary: “Every product is now realized with the same high quality. In addition, automation offers added value by collecting data and thus creating synergy with the basic extrusion,” says Jerome van Bussel.